In the rapidly evolving world of display technology, one term that has been gaining significant attention is the LED invisible display. As industries continue to demand more innovative and versatile display solutions, the role of a LED invisible display factory becomes increasingly pivotal. These factories are at the forefront of transforming how we interact with visual content, offering cutting-edge technology that seamlessly integrates into various applications. This blog will delve into the world of LED invisible displays, exploring their unique features, applications, and the critical role that factories play in manufacturing these revolutionary products.

Understanding LED Invisible Displays

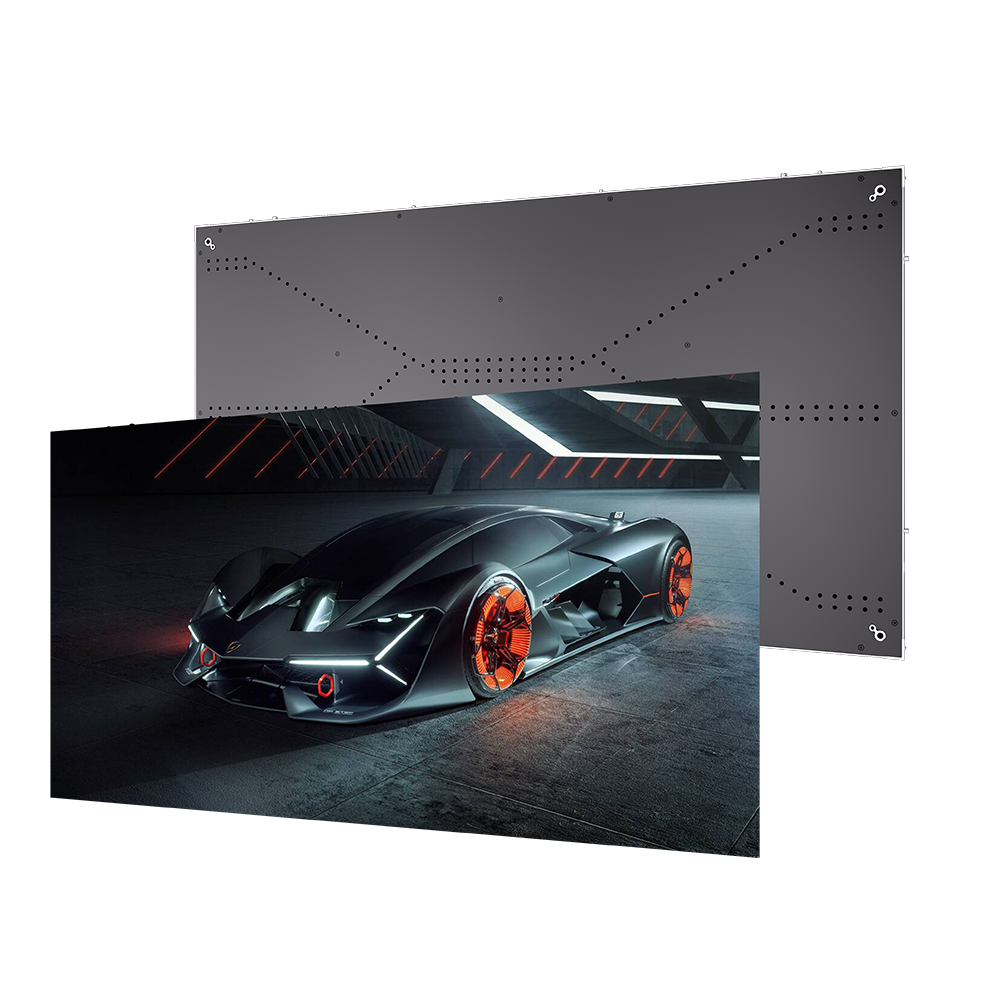

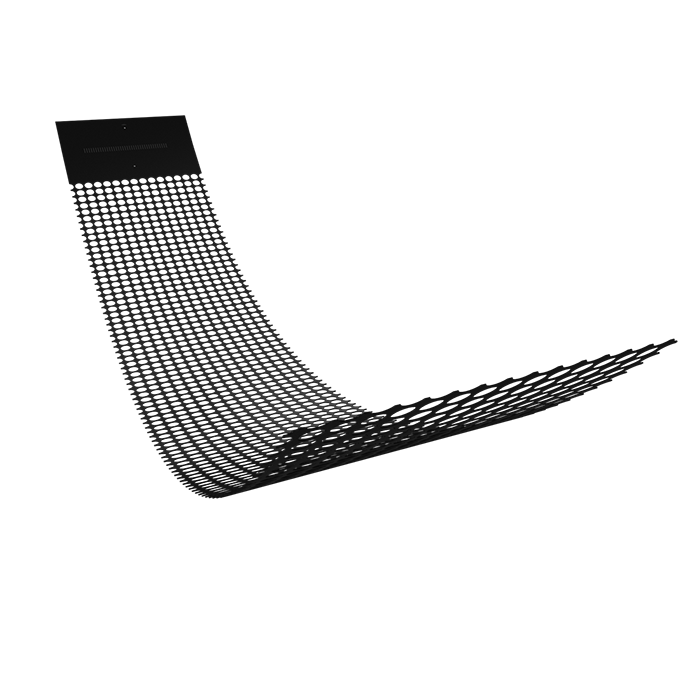

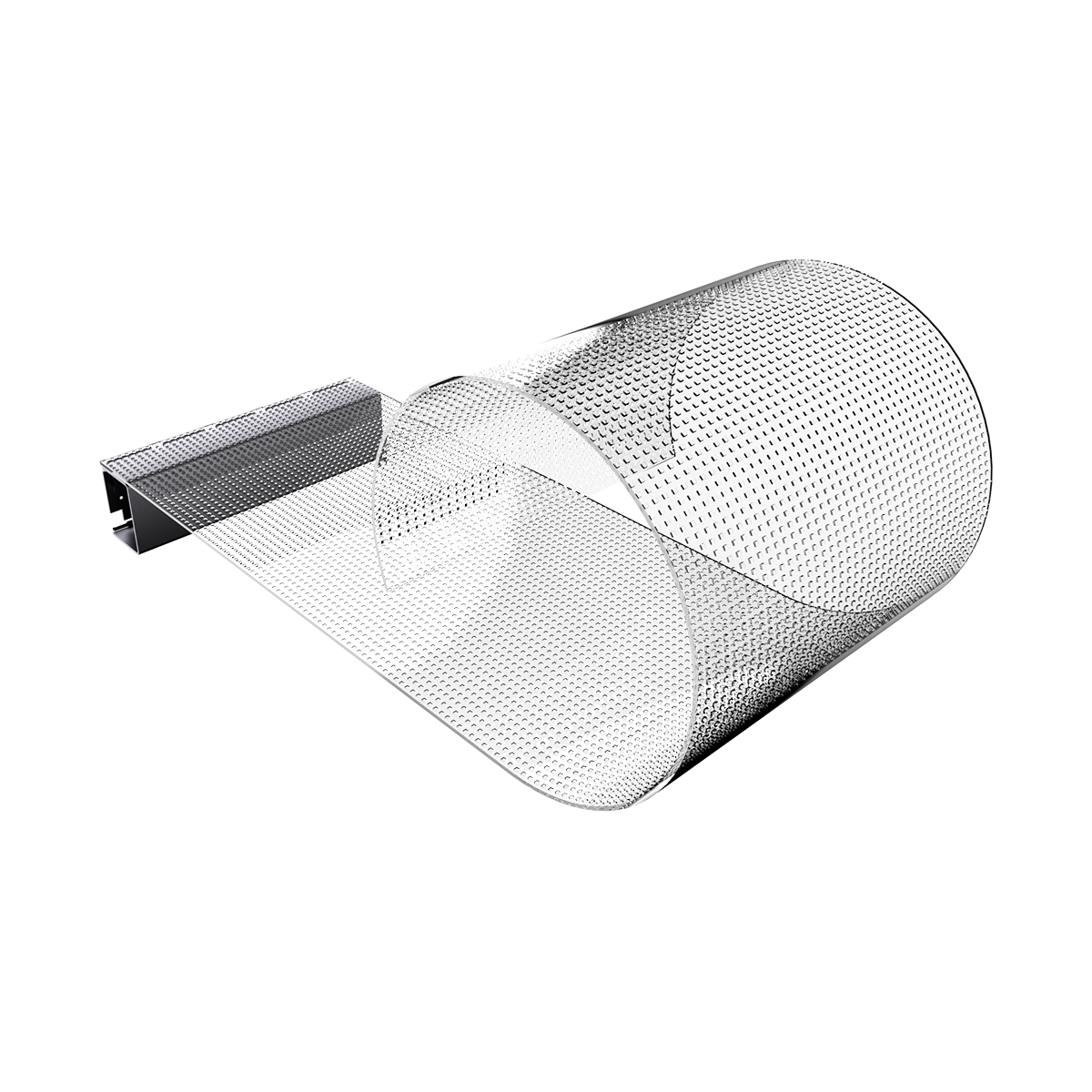

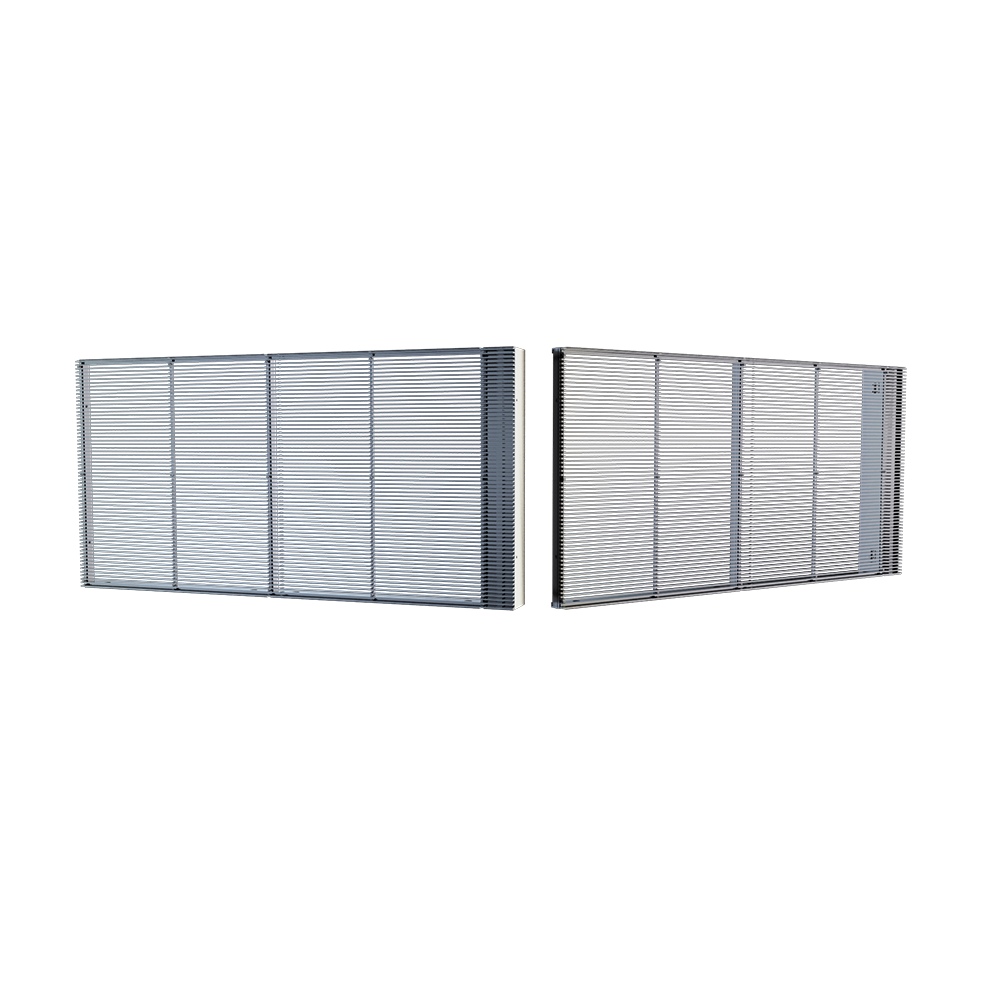

Before diving into the details of a LED invisible display factory, it's essential to understand what an LED invisible display is. Unlike traditional displays that are fully visible at all times, LED invisible displays are designed to blend into their surroundings when not in use, becoming almost entirely transparent or invisible. This unique characteristic makes them ideal for a wide range of applications where aesthetics and functionality must coexist.

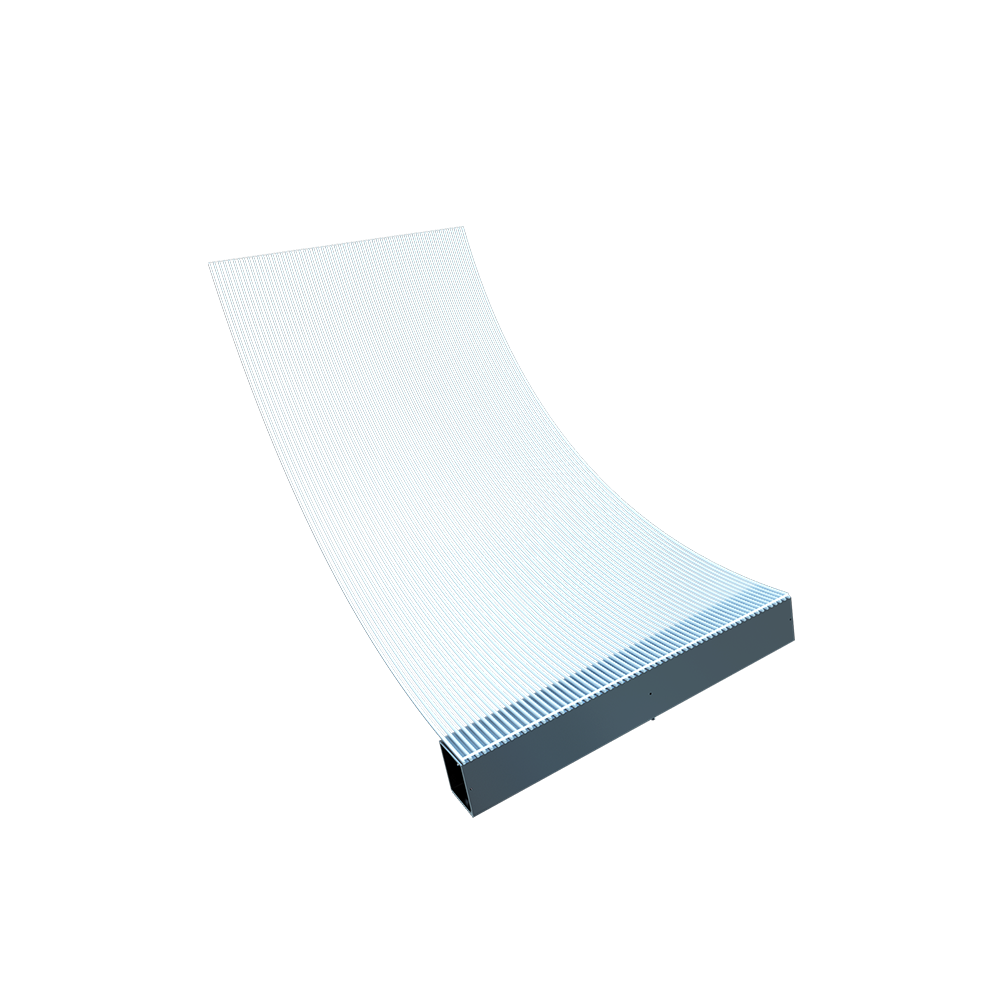

LED invisible displays are built using advanced materials and technologies that allow them to emit light only when activated, creating vibrant and high-resolution images. When turned off, the display surface appears almost transparent, merging with the background. This feature makes LED invisible displays highly versatile, suitable for various environments such as retail stores, museums, corporate offices, and even residential spaces.

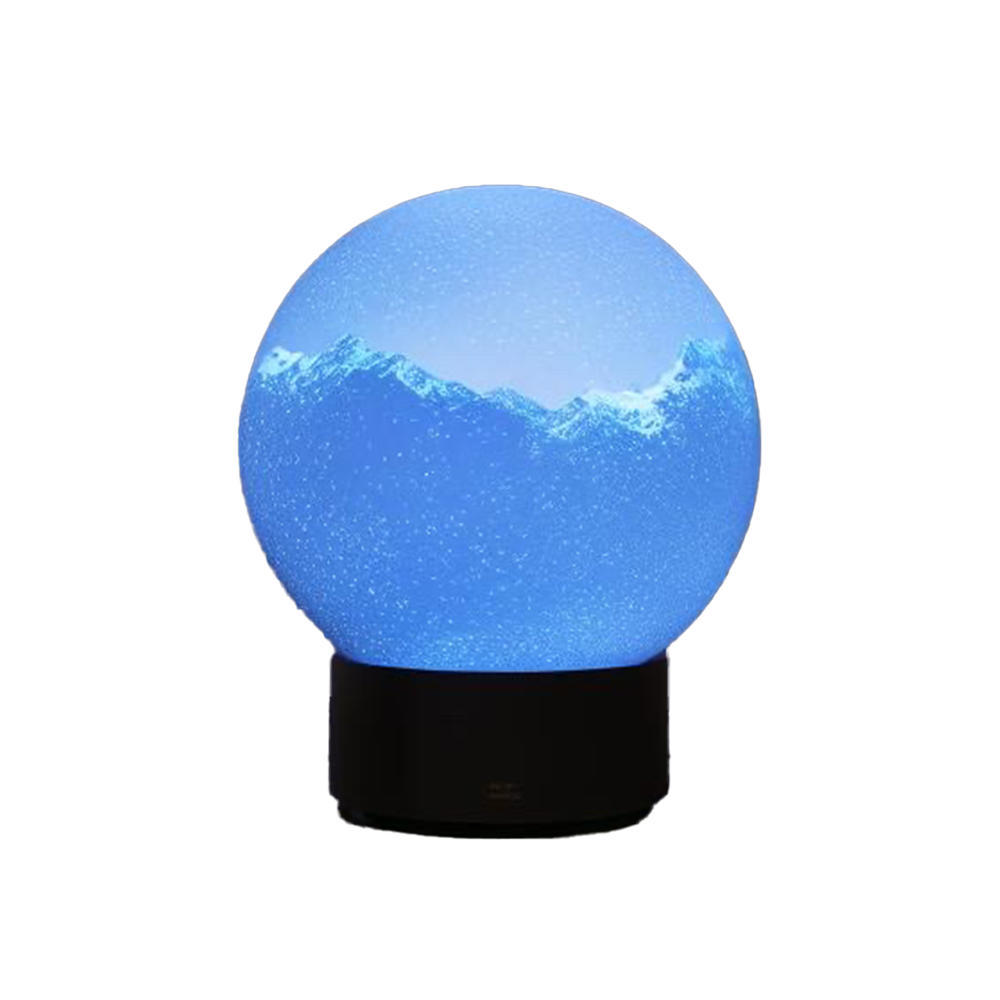

Moreover, recent advancements have led to the development of holographic LED invisible displays, which take this technology a step further by incorporating holographic elements that can create 3D visual effects. This integration enhances the depth and realism of the displayed content, opening new possibilities for creative and immersive applications.

The Role of a LED Invisible Display Factory

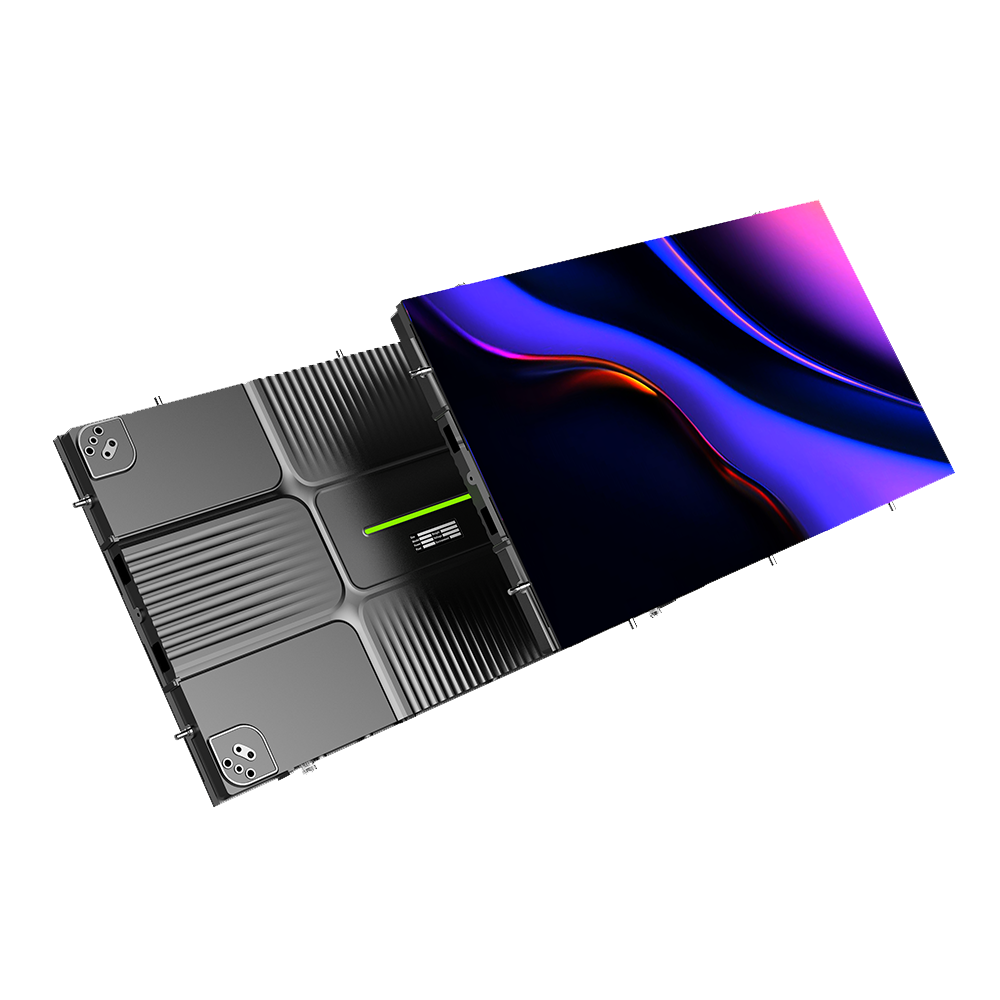

A LED invisible display factory is a specialized facility where these advanced displays are designed, developed, and manufactured. The production process involves a combination of cutting-edge technology, skilled labor, and stringent quality control measures to ensure that each display meets the highest standards of performance and durability.

Factories dedicated to producing LED invisible displays are equipped with state-of-the-art machinery and tools that enable precise manufacturing processes. From the initial design phase to the final assembly, every step is meticulously planned and executed to create displays that deliver exceptional visual experiences. Moreover, these factories often invest heavily in research and development to stay ahead of the competition, continually improving the quality and functionality of their products.

The Manufacturing Process

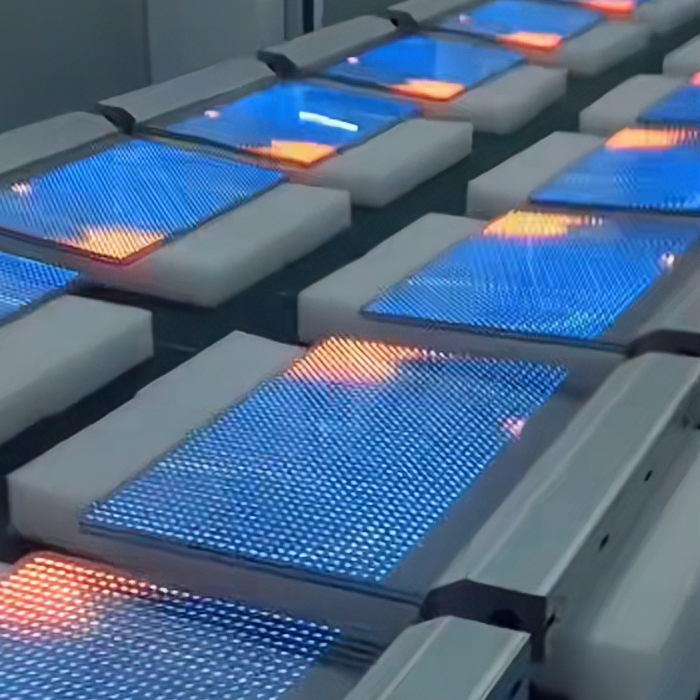

The manufacturing process of LED invisible displays is complex and requires a high level of expertise. It begins with the selection of raw materials, including specialized LED components and transparent substrates. These materials are carefully chosen to ensure that the final product is both high-performing and aesthetically pleasing.

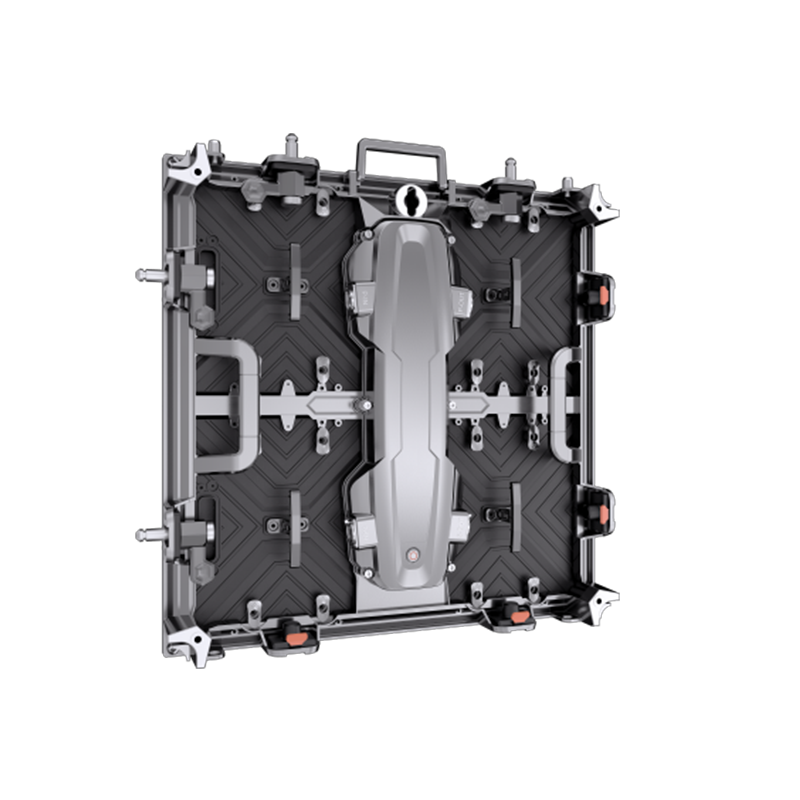

Next, the factory's engineers and technicians work on assembling the display, integrating the LED components with the transparent substrate. This process requires precision and attention to detail, as any imperfections could affect the display's invisibility and overall performance. The components are then tested rigorously to ensure they meet the required specifications, including brightness, resolution, and transparency.

Once the assembly is complete, the displays undergo a series of quality control checks. These checks are crucial in ensuring that each display functions correctly and meets the factory's high standards. Only after passing these tests are the displays packaged and prepared for shipment to customers.

Applications of LED Invisible Displays

One of the primary reasons behind the growing demand for LED invisible displays is their versatility. These displays can be used in various settings, offering unique benefits in each application.

1. Retail Environments

In retail, LED invisible displays are used to create eye-catching advertisements and product showcases that seamlessly integrate with the store's interior design. When not in use, the displays are virtually invisible, ensuring that the store's aesthetics are not compromised.

2. Museums and Exhibitions

Museums and exhibition spaces benefit from LED invisible displays by using them to present information in a non-intrusive way. Visitors can enjoy the exhibits without being distracted by visible screens, while the displays provide additional information when needed.

3. Corporate Offices

In corporate settings, LED invisible displays are used for presentations, meetings, and digital signage. Their ability to blend into the environment makes them an excellent choice for modern office designs that prioritize minimalism and elegance.

4. Residential Applications

LED invisible displays are also making their way into residential spaces, where they are used in home theaters, smart mirrors, and even kitchen backsplashes. Homeowners appreciate the combination of functionality and style that these displays offer.

5. Automotive Industry

The automotive industry is another sector that benefits from LED invisible displays. These displays are used in vehicles to provide information to drivers without obstructing their view. When not in use, the displays blend into the dashboard or windshield, enhancing the vehicle's overall design.

Advantages of LED Invisible Displays

The rise of LED invisible displays can be attributed to several key advantages that they offer over traditional display technologies. These advantages make them an attractive option for various industries looking to innovate and improve their visual communication strategies.

1. Aesthetic Appeal

One of the most significant advantages of LED invisible displays is their aesthetic appeal. Because they become nearly invisible when not in use, they do not interfere with the design of the space in which they are installed. This feature is particularly important in environments where aesthetics are a priority, such as luxury retail stores, high-end corporate offices, and modern homes.

2. Space-Saving Design

LED invisible displays are designed to be thin and lightweight, making them ideal for installations where space is limited. Their ability to blend into their surroundings also means that they do not require additional enclosures or frames, further saving space and reducing clutter.

3. High-Quality Visuals

Despite their invisible nature when turned off, LED invisible displays offer high-quality visuals when activated. They are capable of displaying vibrant colors, sharp images, and smooth motion, making them suitable for various content types, from advertisements to interactive displays.

4. Energy Efficiency

LED invisible displays are also known for their energy efficiency. Because they use LED technology, they consume less power than traditional displays, which is an essential consideration for businesses looking to reduce their energy consumption and lower their operational costs.

5. Customizability

LED invisible displays can be customized to meet the specific needs of different applications. Whether it's the size, shape, or resolution, these displays can be tailored to fit the requirements of any project, ensuring that they deliver the desired impact.

Challenges in Manufacturing LED Invisible Displays

While the benefits of LED invisible displays are clear, manufacturing these advanced displays presents several challenges. A LED invisible display factory must overcome these challenges to produce high-quality products that meet the demands of various industries.

1. Material Selection

Selecting the right materials is one of the most critical challenges in manufacturing LED invisible displays. The materials must be transparent enough to achieve the invisible effect while also being durable and capable of withstanding regular use. Factories must invest in research and development to find the best materials for their displays.

2. Precision Assembly

The assembly process for LED invisible displays requires a high level of precision. Any misalignment or defect in the components can compromise the display's performance and invisibility. Factories must employ skilled technicians and use advanced machinery to ensure that each display is assembled correctly.

3. Quality Control

Quality control is another significant challenge in the production of LED invisible displays. Factories must implement rigorous testing procedures to ensure that each display meets the required standards. This process can be time-consuming and costly, but it is essential for delivering a reliable product.

4. Cost Management

Manufacturing LED invisible displays is an expensive process, primarily due to the cost of materials and the need for specialized equipment. Factories must find ways to manage these costs while maintaining high-quality standards, which can be challenging in a competitive market.

Future Trends in LED Invisible Display Manufacturing

As technology continues to advance, the LED invisible display factory of the future will likely see several trends that will shape the industry.

1. Integration with Other Technologies

One of the most exciting trends in LED invisible display manufacturing is the integration with other technologies, such as augmented reality (AR) and artificial intelligence (AI). This integration will create more interactive and intelligent displays that can adapt to the user's needs and preferences.

2. Increased Customization

As demand for personalized products grows, factories will need to offer more customization options for LED invisible displays. This trend will require factories to invest in flexible manufacturing processes that can accommodate a wide range of specifications.

3. Sustainable Manufacturing Practices

Sustainability is becoming an increasingly important consideration in manufacturing. LED invisible display factories will need to adopt more sustainable practices, such as using eco-friendly materials and reducing energy consumption during production.

4. Expansion into New Markets

As the benefits of LED invisible displays become more widely recognized, factories will likely see an expansion into new markets. Industries such as healthcare, education, and transportation are expected to adopt this technology, creating new opportunities for manufacturers.

Conclusion

The LED invisible display factory plays a crucial role in the development and production of one of the most innovative display technologies available today. As industries continue to seek out new ways to engage audiences and enhance visual communication, the demand for LED invisible displays is expected to grow. Factories that specialize in this technology are at the forefront of this revolution, continually pushing the boundaries of what is possible in display design and functionality. With ongoing advancements in technology and manufacturing processes, the future of LED invisible displays looks bright, promising even more exciting developments in the years to come.